Manufacturing & Design

Overview

I have extensive experience in the design, manufacture, and engineering of equipment for broadcast and film, with a practical focus on camera equipment and optics, cranes, dollies, tracking systems, and remote heads. My work has supported rental companies and technical operations across the UK and internationally, bridging both OEM manufacturing and after-sales re-engineering to meet specific production requirements. This includes specialist work where mechanical systems are adapted for creative demands and non-standard applications.

“Over the many years I've known Phillip, I have found his knowledge and experience with equipment and procedure to be extensive and valuable.” — Ira Tiffen

Engineering & Safety

I am experienced in resolving design, manufacturing and quality control issues, or modifying and adapting equipment beyond its original intent for specialist use in Film & TV.

I’ve carried out maintenance and safety testing on crane systems and hydraulic dollies, and implemented technical modifications in line with rigorous engineering protocols.

I have an exemplary safety record while overseeing cranes, dollies, and remote heads at the companies with which I have been associated.

Defending Manufacturers’ Standards

As part of my longstanding commitment to technical integrity, I have consistently defended internationally recognised manufacturer standards, particularly where these were at risk of being diluted, misapplied, or quietly rewritten through informal agreements or industry 'guidance'. I have actively opposed the misuse of standards agreements as a means of regulatory overreach, challenging practices that could distort competition, restrict market access, or undermine legal and operational clarity.

My approach is grounded in both practical experience and legal principle, ensuring that safety, transparency, and quality are upheld without enabling back-door control or market foreclosure. This includes challenging attempts to introduce technically unsound requirements, advocating for proportionality and due process, and ensuring standards leadership reflects ethical and professional responsibility.

Competition Law identifies and prohibits agreements that “Have as their object or effect, the restriction of competition.” It recognises that the adoption of agreements, including those on Safety, may be used in order to foreclose markets.

Defending Patents & Design Rights

I have also served as a professional witness in two high-level legal cases: one involving a US design rights dispute over telescopic cranes, and another in a US/EU patent infringement case between competing manufacturers, concerning design the features of camera dolly systems. In both instances, my evidence was grounded in practical knowledge, operational context, and long-term industry standards, contributing to successful outcomes.

Cranes & Jibs

I hold a longstanding reputation in jib system re-engineering, with over 20 years of experience working hands-on with Stanton Jimmy Jib systems, both on set and through substantial technical modifications under LEQ Ltd.

Working beyond standard configurations, I have modified jibs and cranes for specialist mounting and rigging solutions, ensuring full mechanical integrity and on-set reliability. Original modifications designed and built by me remain in active production use today.

This includes an extensive upgrade of the Jimmy Jib, dubbed the Jimmy Jib 'Extreme', which exceeded factory specification across structural design, corrosion resistance, hardware strength, assembly efficiency, and practical performance.

Notable enhancements included:

-

Custom stainless steel bolts and Helicoil thread inserts to protect threads and reduce maintenance

-

Hard-anodised jib arm surfaces for internal and external corrosion protection, replacing easily worn painted or Alochromed finishes

-

Hardware upgrades including M16 zinc-plated eyebolts, solid lock nuts, and stainless steel shackles rated at 3800kg

-

A Euro Boss coupling for fast, secure compatibility with a variety of base systems

-

A reinforced remote head with precision bearings, internal breakout box, dual BNC lines, and low-loss accessory power lines

I also collaborated directly with the designer of the Egripment Scanner Crane, delivering custom design modifications required by VFG PLC for operational rollout.

LEQ All-Terrain Tracking Base (ATB)

The LEQ All-Terrain Tracking Base (ATB) was a re-development of the MK I Tulip base, engineered to deliver universal compatibility, field robustness, and configuration flexibility. Designed and built in the UK in full consultation with Egripment, the base was optimised for real-world production needs.

The ATB features a two-stage column, allowing for different height profiles depending on jib size:

-

Short column, for jibs up to 24ft

-

Tall column, for jibs up to 40ft

The column incorporates a 4-way levelling head with universal mounting compatibility, accepting:

-

Euro Boss coupling

-

Moy/Mitchell

-

Vinten

-

Chapman Bolt

The heavy-duty chassis supports a variety of wheel configurations:

-

Hard wheels for smooth-floor and studio use

-

Pneumatic wheels for uneven terrain and OB shoots

-

Nylon track wheels for rail-based tracking shots

Other features include:

-

Wind-up jacks for load levelling

-

Reinforced, removable leg-struts for transport and servicing

The ATB is actively used by Sky, who operate two units for productions including Soccer AM and Cricket AM, citing its versatility, compatibility, and reliability across changing environments.

Equipment Production & Camera Support Systems

I assembled the final production run of Skymount, a British CAA-certified helicopter mount.

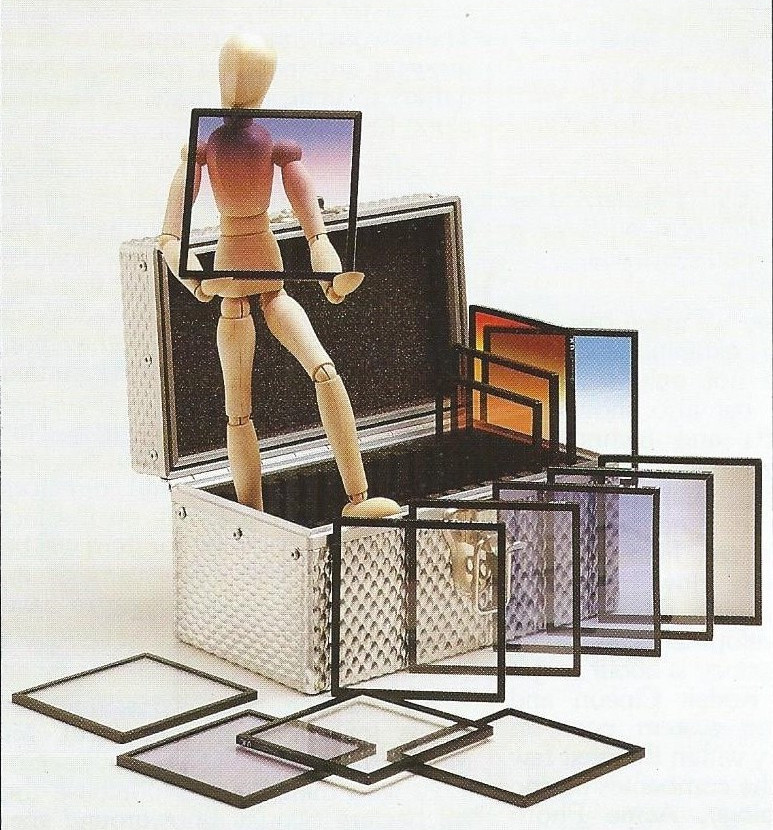

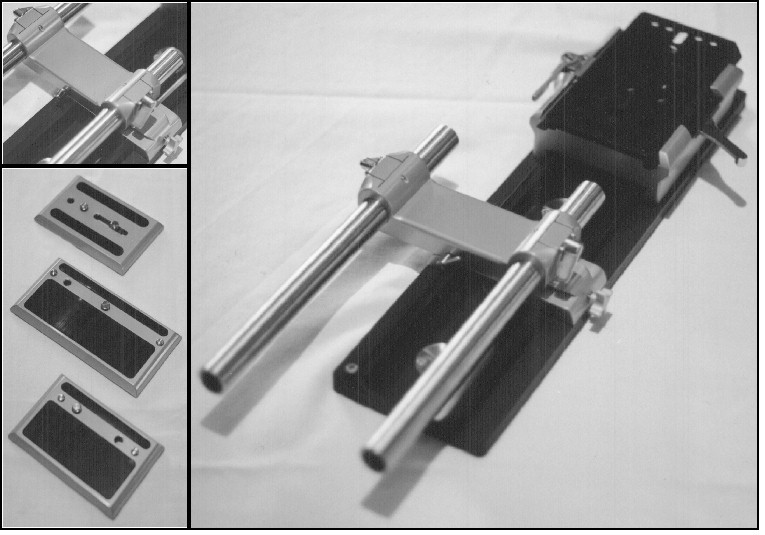

I was involved in the manufacture and dispatch of the Focus Track Systems, including factory visits, repairs, maintenance, and shipping.

I’ve often been called on to investigate and resolve faults in cranes, dollies, or grip systems, whether due to manufacturing issues, misuse, or field conditions.

I also gained an international reputation for refurbishing Elemack camera dollies, restoring ‘lost’ units to a professional standard.

Turning Convention on its Side

I worked with Karl Kelly and the team at VFG to mount my 35mm VistaVision camera in a non-conventional orientation, rotated 90 degrees to the normal film plane, for the IMAX production The Human Body. Unlike most modern film or digital systems, the Paramount Butterfly VistaVision cameras of the 1950s were not designed for flexible use. Adapting them for vertical shooting required extensive planning, modification, and safety oversight. The rig performed consistently across a full year of production.

Optics, Filters & OEM Training

My training in optical systems includes OEM-manufacturer training at Panavision Los Angeles, where I was taught lens and camera servicing, collimation, and MTF (Modulation Transfer Function) testing. This built strongly on top of my existing training at Cinefocus, VFG, and on courses with Sony, Kodak and others, providing a strong foundation in precise mechanical alignment and performance diagnostics at manufacturer level.

Custom Engineering Solutions

Other notable examples of my design and fabrication work include:

-

Universal FI+Z Pan Bar Bracket – enabling flexible compatibility for focus, iris, and zoom systems.

-

360˚ Cage Offset Motor Bracket – optimising lens motor placement in confined rigging environments.

-

Universal Steadicam Bridge-Plate – fast transition from Steadicam to tripod in moments, not minutes.